Excellent quality Cationic Silicone Oil - 60748 Silicone Softener (Hydrophilic, Deepening & Especially suitable for vulcanized black fabrics) – Innovative

Excellent quality Cationic Silicone Oil - 60748 Silicone Softener (Hydrophilic, Deepening & Especially suitable for vulcanized black fabrics) – Innovative Detail:

Features & Benefits

- Excellent hydrophilicity.

- Perfect applicability: Its property of nanoscale microemulsion can ensure the stability under high shear and wide pH range. During use, there will be no roll banding, sticking to equipment, oil floating or demulsification.

- Has great deepening effect on vulcanized black color fabrics. Effectively improves dyeing depth 20~30% and reduces dyes.

- Has 20~30% deepening and brightening effect on medium and dark color fabrics, as activated black, bright red and royalblue, etc. without negative effect on color fastness.

- If the fabric needs dyeing modifying or color repairing, it is easy to strip silicone.

Typical Properties

| Appearance: | Transparent emulsion |

| Ionicity: | Weak cationic |

| pH value: | 6.0±0.5 (1% aqueous solution) |

| Solubility: | Soluble in water |

| Application: | Fabrics in medium and dark color, especially vulcanized black |

Package

120kg plastic barrel, IBC tank & customized package available for selection

TIPS:

Chemical finishing processes

Chemical finishing can be defined as the use of chemicals to achieve a desired fabric property. Chemical finishing, also referred to as ‘wet’ finishing, includes processes that change the chemical composition of the fabrics that they are applied to. In other words, an elemental analysis of a fabric treated with a chemical finish will be different from the same analysis done prior to the finishing.

Typically chemical finishing takes place after coloration (dyeing or printing) but before fabrics are made into garments or other textile articles. However, many chemical finishes can also be successfully applied to yarns or garments.

Chemical finishes can be durable, i.e. undergo repeated launderings or dry cleanings without losing effectiveness, or non-durable, i.e. intended when only temporary properties are needed or when the finished textile typically is not washed or dry cleaned, for example some technical textiles. In nearly all cases, the chemical finish is a solution or emulsion of the active chemical in water. Use of organic solvents to apply chemical finishes is restricted to special applications owing to the expense and the real or possible toxicity and flammability of the solvents employed.

The actual method of finish application depends on the particular chemicals and fabrics involved and the machinery available. Chemicals that have strong affinities for fiber surfaces can be applied in batch processes by exhaustion in dyeing machines, usually after the dyeing process has been completed. Examples of these exhaust applied finishes include softeners, ultraviolet protection agents and some soil-release finishes. Chemicals that do not have an affinity for fibers are applied by a variety of continuous processes that involve either immersing the textile in a solution of the finishing chemical or applying the finishing solution to the fabric by some mechanical means.

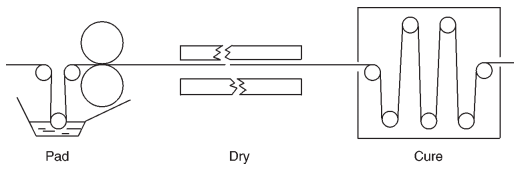

After application of the chemical finish, the fabric must be dried and if necessary, the finish must be fixed to the fiber surface, usually by additional heating in a ‘curing’ step. A schematic diagram of a pad–dry–cure process is shown as below.

Product detail pictures:

Related Product Guide:

Anti-migration agent can improve the stability of dyeing bath, which is to prevent dyeing defects, as color difference and white core, etc. due to dyes migration. Excellent quality Cationic Silicone Oil - 60748 Silicone Softener (Hydrophilic, Deepening & Especially suitable for vulcanized black fabrics) – Innovative , The product will supply to all over the world, such as: Bogota, Azerbaijan, USA, Mercerizing Wetting Agent 11008 is mainly composed of fatty alcohol sodium sulfate complex. It is suitable for fabrics of cotton and cotton blends. It can impart cotton fibers durable luster like silk and improves dimensional stability of textile. Mercerizing Wetting Agent 11008 is eco-friendly. It has excellent penetrating property in 21~30 °Bé caustic soda solution. It is highly stable in high concentration alkali liquor.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.